Car Collision Vs Copper Collision Diagrams

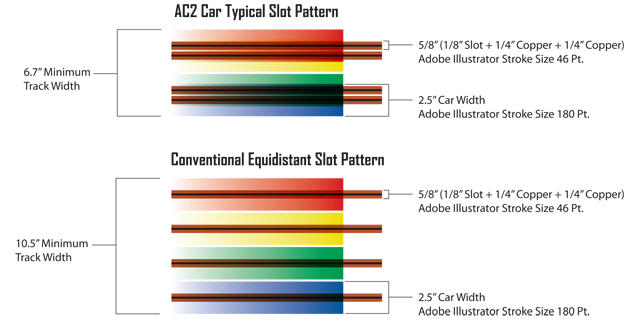

Building on my last post about AC2Car Lane Spacing and Typical Slot Car Spacing and the use of graphic programs such as Adobe Illustrator, here are some visuals regarding what I like to call Car Collision Diagrams and Copper Collision Diagrams. If you recall with AI (Adobe Illustrator) you can draw a singular line and apply visual stroke widths to it. This can enable you to quickly see good and bad areas in your digital track file prep. With a stroke width applied to a line of 180 points (Representing the width of a car) you can create virtual slots and see how cars will mingle with one another. Good and bad can come of this. The most obvious is when you have typical slot car spacing you never want these car lines to run together. With AC2Car its a bit different with the ability to pass. I suggest for a better understanding of the principle slot layout for AC2Car visit our track building page.

Now likewise and more important to AC2Car is taking those same AI lines and applying the stroke value for copper width (Slot and two pieces of copper is a 46 point width) to see where you might have copper from one lane touching an adjacent lane. This is paramount with AC2Car’s tight lane spacing. By going back and forth between car collision stroke width and copper collision stroke width you can succesfully plan your track virtually before routing.

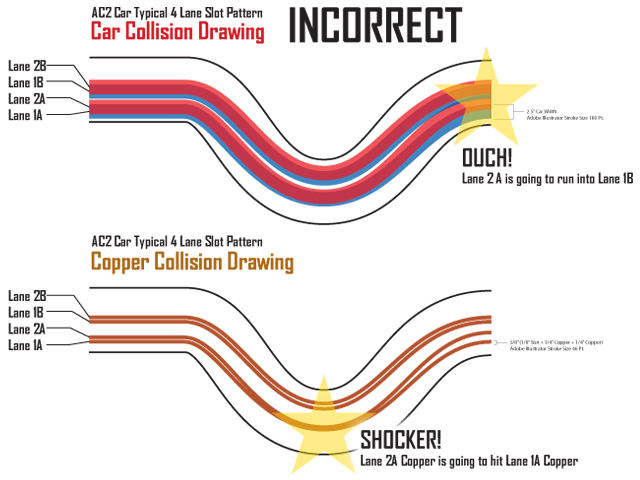

Here is the same section of track, this first image is Correct with NO problem areas with car or copper collisions:

Now this Second Image you can see in the Car Collsion Diagram where Lane 2A is going to hit Lane 1B. Also in the Copper Collision Diagram you can see where lane 2A and 1A Copper would touch one another, ohh ouch shocker!

And there you have it! For Standard AC2Car Spacing, these simple diagrams can help you design your track and once you’re finished you can use the very same files for routing. For the daring you might try squeezes in areas where no cars can pass, or wide open even spaced areas where all lanes can pass integrated into your track. Careful though these types will require more experienced respectable drivers to avoid car on car crashes (From experience on my WLF1 Ring)